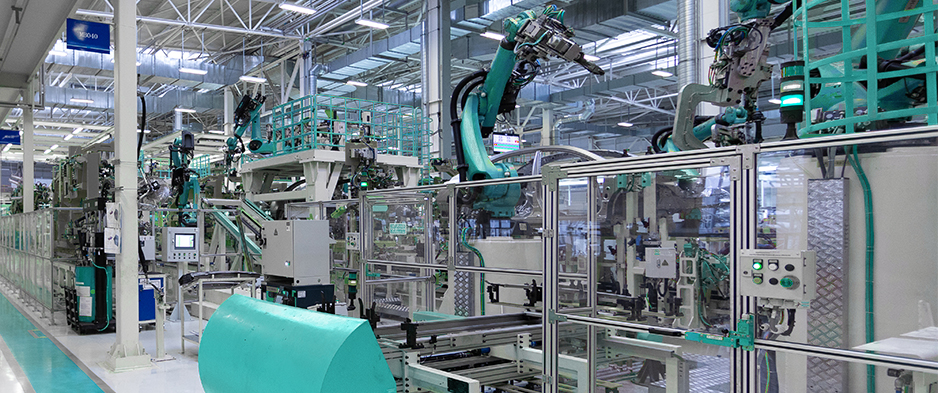

There are many advantages in using a highly integrated robotic cell in industry. These complete systems improve the production process in many ways, from efficiency – reducing production costs and waste – to product quality.

Let’s see the main benefits of these solutions.

Industrial robotic cells: main advantages for manufacturing

Production and labor cost reduction

Highly integrated robotic cells combine speed and precision, therefore allowing to reduce waste. In addition, they guarantee maximum autonomy of the robots. This makes it possible to optimize work and reduce costs even in the most demanding high-volume production applications.

Product quality improvement

Companies can reduce or eliminate the need for lengthy manual inspections and, at the same time, ensure the highest product quality. Robotic cells provide fast and accurate quality testing, making metrology easier and faster. As a result, they reduce failures, errors and defects.

More flexibility

Robotic cells such as ESA Robotics’ use robots as an “arm” to move and control the tool. This offers enormous advantages in terms of flexibility. In addition, you can customize the cells according to your needs and processing.

Safety

Ensuring operators’ safety is one of the most important aspects in the industry. Especially when it comes to handling and managing powerful machinery such as robots: activities that, if not done correctly, can be dangerous. Preventing the risk of injury and damage is one of the main benefits of robotic cells.

Improve overall flow and efficiency

Highly integrated robotic cells allow robots to operate at their full capacity and speed. By customizing the cell layout to your specific application process, you can increase the speed at which a part can be completed and moved along the production line. In this way, while a given part is completed inside the cell, operators can load and unload other parts.