Augmented reality (AR) is one of the latest technologies used in manufacturing for data management. Successfully used in multiple sectors, including healthcare and entertainment, in recent years AR has been progressively integrated with other Industry 4.0 enabling technologies, such as Big Data Analytics and IoT.

The main advantages of augmented reality are its speed and high level of interactivity. Two fundamental qualities to access and manage data in real time and more efficiently.

Augmented reality applications for data management

Augmented reality is basically a digital enhancement of the real world. This technology superimposes information (images, text, sounds, etc.) on the reality we see. More importantly, it allows this information to integrate with our reality, becoming interactive.

In manufacturing, this technology finds applications that go beyond the simple superimposition of multimedia. The ultimate goal is to superimpose data, statistics, instructions and other fundamental information in the production context. For example, by simply looking at a machine through an AR device, the operator is able to access valuable data, such as status, consumption, temperature, performance, and much more.

As a result, AR contributes significantly to increase productivity. In fact, some studies already show an improvement of up to 50% in people who work with augmented reality solutions.

The same applies to data management, being AR synonym with greater data accessibility. In fact, it enables a new and more efficient way to visualize, manage and use data to optimize the production process. With augmented reality, any information becomes immediately available and contextualized, with no effort or waste of time. From maintenance to energy efficiency and performance, companies can obtain several advantages.

ESA’s AR solution

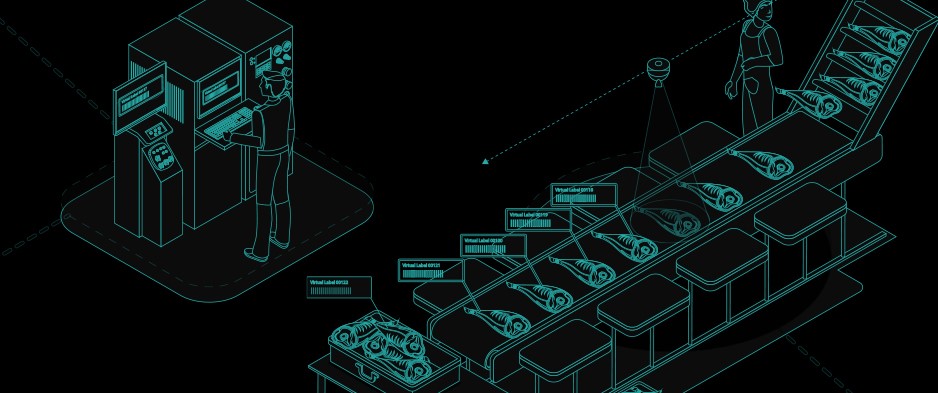

Recently, ESA has presented an augmented reality solution for virtual labeling. Based on visual recognition and tracking algorithms, it improves product traceability. Augmented reality was key in this project, which we integrated with video tracking and our SCADA Crew.