Though manufacturing took a hit between 2020 and 2021, the global pandemic hasn’t stopped innovation. The new context has in fact reshaped industrial automation and the way we work in general. As a result, new needs, goals, and trends have emerged.

MOREHigh performances in a compact solution. The new family of industrial PCs ESA LUMIA Book opens a new chapter in the path of technological innovation. Flexible, customizable and with a high degree of connectivity, they are the ideal devices in a Smart Factory context.

MOREIndustry 4.0 and Green Economy today appear increasingly linked, if not inseparable. In recent years, the concept of sustainability in manufacturing has become one of the identifying elements of the fourth industrial revolution.

MOREIn 2011, 10 years ago, the term Industry 4.0 made its debut at Hannover Messe in Germany. Since then, this new industrial era has conveyed concepts and technological innovations that revolutionized the global manufacturing sector.

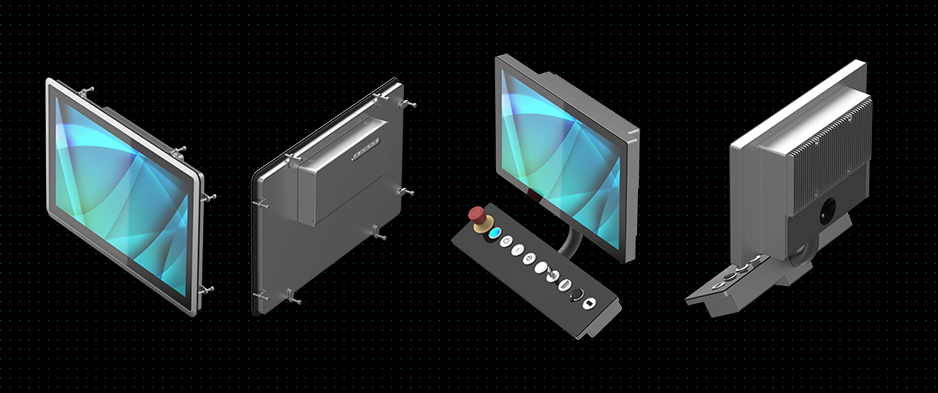

MOREA flexible and dynamic device for an innovative work experience. ESA Lumia is the modular solution that promotes a new concept of HMI, visualization and control.

MOREIt’s a Yes to the refinancing of the New Sabatini in the 2022 Budget Law. The maneuver amounts to a total of about € 30 billion, of which € 8 billion for the internationalization of companies and € 900 million to refinance the Nuova Sabatini in the period 2022-2026.

MOREBetween cyber-attacks, catastrophic events and human error, the primary data centers of companies are constantly exposed to threats that can cause loss of profits, damage to the image, leak of sensitive information, and delays in production or orders evasion.

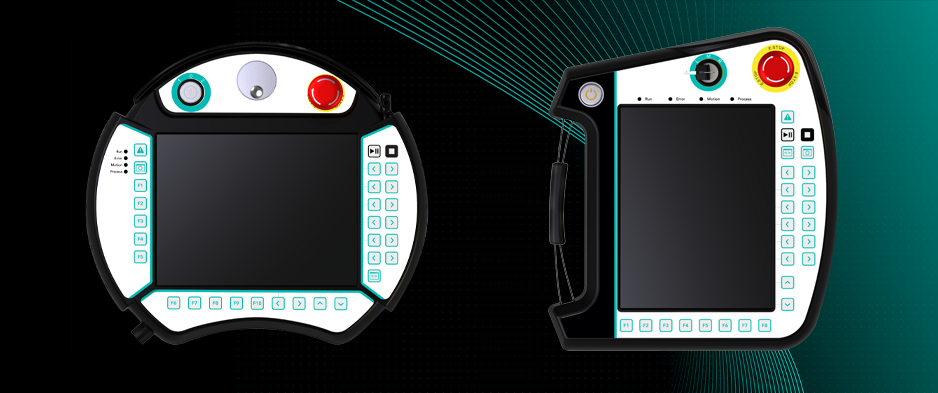

MOREWith the decentralization of production in Industry 4.0, there is a growing need for smart devices suitable for an increasingly dynamic manufacturing context. The confluence of technological developments such as digitalization and the Internet of Things leads to new ways to control, connect, and manage production devices.

MOREWith the Industrial Internet of Things and the connected machinery increase in smart factories, the volume of available data continues to grow. For this reason, we need a production model capable of processing, analyzing, and optimizing all those data, so that it can be valuable in terms of productivity and efficiency.

MOREIn Industry 4.0, data plays a central role. With the development of faster networks, wider storage space and new sensor technologies, companies have access to ever higher volumes of information. Sometimes even too much…

MORE