ESA S.p.A., specialized in the development of hardware and software solutions that allow exploiting the potential offered by data to make production more sustainable, efficient, safe and digitized, is now focusing on robotics. Through an extraordinary management operation, the company based in Mariano Comense (CO) has in fact invested in QDesign S.r.l. whose QD Robotics brand is well established on the market. This operation fostered the creation of the ESA Robotics division.

MOREIn these past years, the number of HTML5-based applications has been growing, and not just in the consumer and business market. This technology has become the web programming standard in the industrial sector, thanks to its benefits in terms of flexibility, mobility and efficiency. Let’s see the benefits of HTML5-based industrial management and control interfaces. ESA’s solutions included.

MOREHMIs driven by artificial intelligence make it possible to develop increasingly automated industrial production systems and to accelerate the innovation processes of companies according to the paradigms of Industry 4.0.

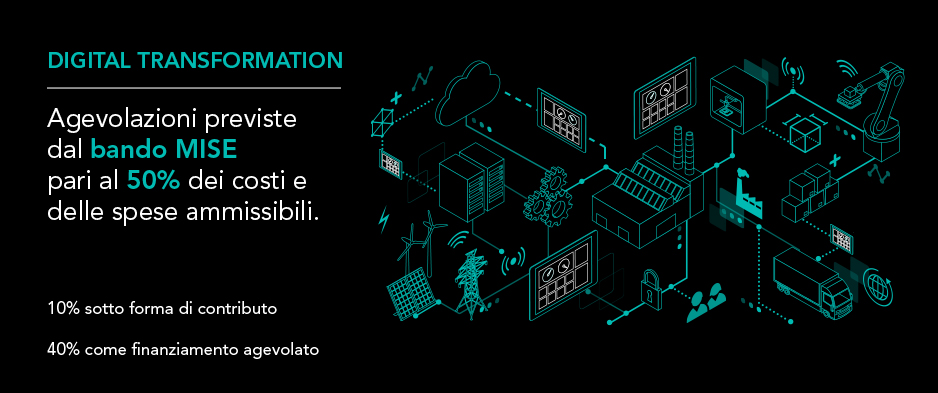

MOREDigital Transformation: the MISE call for SMEs arrives. From December 15th 2020, Italian companies will be able to request access to contributions and funding for the development of projects for the implementation of digital tools and enabling technologies of the Factory 4.0 Plus Plan.

MOREIndustrial rugged tablets are designed to withstand even the most extreme production conditions.

MOREIn the past years, we have witnessed the growing integration between IT (Information Technology) and OT (Operational Technology). Especially in production, industrial automation applications now communicate with the corporate IT network.

MORESPS Italia doesn’t give up. The tenth edition of Italy’s leading fair for automation and smart, digital, and flexible manufacturing will take place from 28 to 30 September 2020. However, this year the community will meet in a completely new digital dimension.

MOREThe fifth generation of mobile network will redesign the quality of connection in production plants. And while companies are preparing to unlock an unprecedented level of accessibility and communication, experts are expecting a step forward in the history of the Internet of Things and Industry 4.0.

MOREWhat are the advantages of HMI in packaging? From reconfiguration speed to actions intuitiveness, the right HMI device can make the difference between an efficient and an unproductive one.

MOREDigital signage uses IoT, information technology and smart devices (such as monitors) to make production more efficient and to automate communication within the plant. From displaying alarms to prevent malfunctions to product recognition, this innovative technology has enormous potential in Industry 4.0.

MORE