What is the role of collaborative robots, or cobots, in Industry 4.0? In Smart Factory and IoT era, this new technology finds its perfect location.

MOREAfter finance, blockchain has approached the complex field of online security. Investing in cybersecurity has become a priority for all the biggest companies…

MOREWhen it comes to augmented reality, industry is one of the most promising fields of application.

MORE“Think Electric!” This is the philosophy of the new ESA linear tubular motors, designed to increase energy saving in industry and improve your performance. An efficient, flexible and powerful solution, ideal for all major industrial sectors.

MOREA single complete Drives & Motors solution for cost-sensitive applications. This is the essence of ESA Servo Package, the new drive-motor bundle designed for packaging, positioning table control, delta robot, conveyor belts and automation applications in general.

MOREWhat are the main industrial trends of 2019? The industrial sector keeps evolving, with new technologies, needs and developments thatleave their mark on the market. This year, 5G and Industrial IoT (IIoT) stand out as the two most influential and talked about trends.

MORESPS Italia 2019 is ready to talk about smart, digital and flexible industry. It’s almost time for the 9th edition of the industrial automation and digitalization exhibition, which will take place in Parma from May 28 to 30.

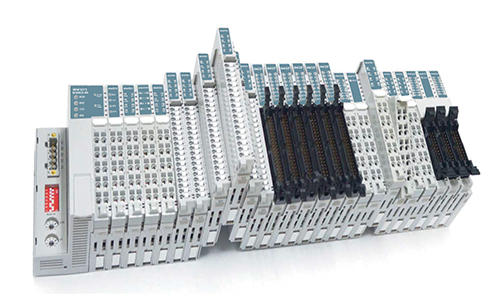

MOREMore connectivity and configurability: ESA Automation launches the new network remote I/O EW620, the latest addition to the range of industrial automation solutions Esaware. Designed according to the IoT and Industry 4.0 principles, this new device presents innovative features such as the possibility to connect up to 63 modules and the integration of ten fieldbus.

MOREFor the past decades, the evolution of the concept of human-machine interface has defined the industry. Today, with trends such as the Internet of Things and digitalization, we need increasingly sophisticated and interconnected HMI systems to operate in production plants. In all industrial sectors, from automotive to the health sector, companies need interfaces that can make operations as immediate and intuitive as possible. Just like our everyday devices, such as smartphones and tablets. That is one of ESA Automation’s main goals. Our team of technicians and IT experts is constantly working on HMI solutions that can integrate all the Industry 4.0 principles. Starting with ERGO, our new all-in-one control system.

MOREGreat news: the Nuova Sabatini and the hyper-depreciation have been reconfirmed by the Ministry of Economic Development. The government has financed 480 million euros to encourage and facilitate the purchase of new machinery, plant and equipment by SMEs. On February 7th 2019, it became possible to submit applications, according to Directorial Decree no. 1338 of January 28th 2019.

MORE