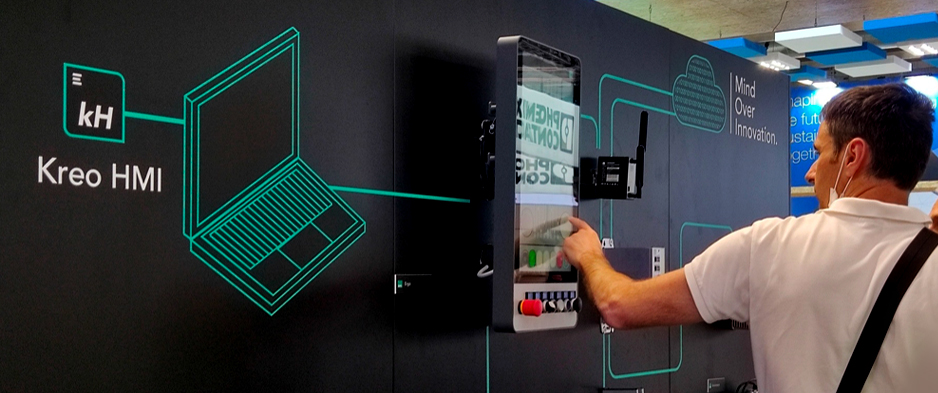

SPS Italia 2022 was a success, hinting multiple prospects for the future. From 24 to 26 May, 36,522 visitors and 802 exhibitors gathered in Parma to share an itinerary in industrial automation and digitalization. The journey highlighted the most innovative technologies for Industry 4.0, including some of ESA’s latest solutions.

MOREHigh performance and maximum flexibility, this is the formula of the new MOTUS servodrive to increase productivity.

MOREDigital manufacturing is synonymous with Industry 4.0 and consists in the integration of the latest technologies and data analysis techniques into the production process to make operations smarter, more flexible, and efficient.

MORESelling solutions rather than products. This is servitization, a business model that exploits digitalization and new technologies to offer more customized, flexible, and efficient solutions.

MORETo ensure greater safety and functionality, operators need mobile and flexible devices. To this end, ESA has created the LUMIA Handheld range, the ideal to visualize and control the system near the moving part.

MOREOPC UA was adopted as the standard for Industry 4.0 to support the digital transformation of companies. From connectivity simplification to greater security, the OPC UA standard plays a decisive role in the digital age.

MOREConsidered a key catalyst for Industry 4.0, 5G is laying the foundations for the digital transformation of businesses and will have a decisive impact on production in the coming years. Here are the main benefits and prospects for using this technology.

MOREHIDRA switches with industrial case complete ESA’s range of Industry 4.0 solutions. Available in unmanaged, managed at Layer 2 and Layer 3 variants, these devices offer protocol integration for redundancy, security features and simplified programming.

MORERussian-Ukrainian conflict: will it be cyber war? As the conflict escalates and the EU and US confirm their support for Ukraine, experts question the possible global cyber war.

MORESPS Italia 2022 “We love to go live” was officially presented. The reference fair for the smart, digital and flexible industry returns to Fiere di Parma from May 24th to 26th. People, technologies and perspectives are the focus of the 22nd edition, which will be a global opportunity to learn about new industrial trends and discuss the hottest topics of the industry of the future.

MORE