The industrial transformation underway is supported by new technologies on which companies base their smart manufacturing strategies. Among these, digital twins have gained increasing momentum, especially in recent years, in correlation to the metaverse. From reducing manufacturing costs to improving business process efficiency, the potential of digital twins is evident in numerous applications.

The role of digital twins in industry

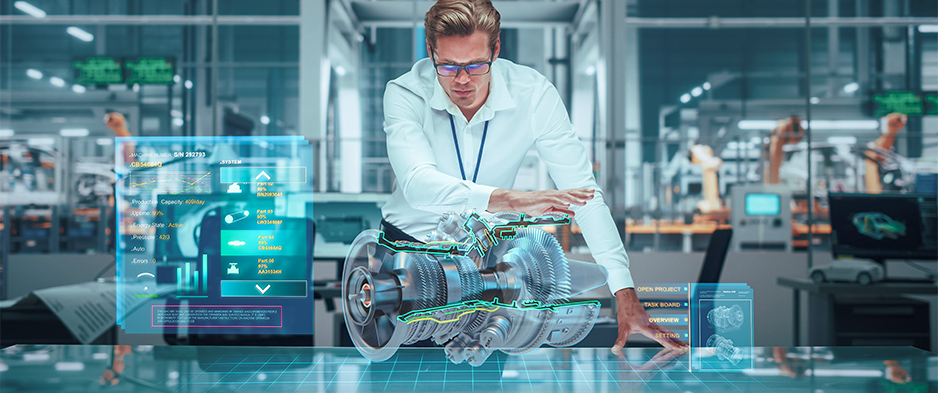

A digital twin is an automated digital representation of a physical device or item. Essentially, it is the virtual replica of the operating dynamics of IoT systems within the production plant. For example, a jet engine. However, in its full expression, this technology can lead to the creation of a digital model of much larger objects and realities, such as buildings, wind farms or even entire cities.

The most useful application of digital twins is to understand even more deeply how the systems and products that a company intends to build will behave. In fact, their use makes it possible to collect data on processes to predict their real functioning in the future. Thanks to machine learning and big data, these virtual models become fundamental factors for promoting innovation, improving performance and strategic and technological trends, preventing breakdowns, etc. This is a huge advantage, enabling enterprises to replicate virtually all elements and dynamics of how their devices and systems will respond during their life cycle.

Digital twins: all the advantages for production

Faster risk assessment and higher productivity

Testing and validating a product are a complex task, especially when it has multiple features. Thanks to digital twins, enterprises can use a virtual environment to do this. This allows engineers to test the product in every aspect and in different scenarios to improve it even before building a prototype (as it was necessary to do previously). This helps improve risk assessment and accelerate new product development, cutting time-to-market and increasing productivity.

Real-time tracking

Today’s manufacturing facilities are predominantly Cloud and IIoT based, with machinery, resources and devices all connected to each other. In this context, many companies use digital models to monitor the production chain in real time. This allows them to gain insight into the physical system and make the necessary changes to improve operations and save money and resources.

Predictive maintenance

Predictive maintenance in turn revolutionized the way we thought about the manufacturing industry. Without it, businesses are forced to schedule regular maintenance to keep machinery running smoothly. This results in production disruption, with possible delays and financial losses.

With what has been said so far, it is easy to imagine how useful digital twin technology is in the predictive maintenance process. In fact, it allows you to generate data in real time and identify any problems within the system. This data can then also be used to run future simulations and pinpoint when exactly a machine will break down or need service.