Lean Manufacturing’s time has come or will it evolve with Industry 4.0?

Experts have spent many hypotheses on this question. In ESA Automation, we believe in a future where lean production and Industry 4.0 not only can coexist, but are connected through an important bond.

What is Lean Manufacturing and how it has changed the industry

Lean Manufacturing is an industrial philosophy that consist in simplifying as much as possible the production process, so as to maximize resources and minimize waste.

The two scholars Womack and Jones used this term for the first time in their 1990 book “The machine that changed the world”. In fact, they focused on the comparison between Toyota and the main automotive houses of the world, highlighting the clear superiority of the Japanese brand in terms of productive efficiency. Hence, the idea of lean manufacturing, which presents five principles to increase efficiency and productivity:

- Define value, from the client point of view.

- Map the value stream, which consists in all necessary steps to create a product and deliver it to the client, cutting waste.

- Create flow, to execute all steps.

- Establish pull, producing only when necessary.

- Seek perfection.

Lean Manufacturing after Industry 4.0

From what you have read up to this point, it is clear that Lean Manufacturing is still a current approach and perfectly aligned with the new paradigms. In fact, efficiency is now more than ever the number one requirement in industry: for this reason, we believe that the values of Lean Manufacturing will not only have room in Industry 4.0, but will become even more important. Only the approach to achieving its goals will change.

While the first three industrial revolutions have been dictated by technical innovations (mechanical production/steam, mass production/production chain, automated production/PLC), Industry 4.0 is born from the Internet and the ability to exchange huge volumes of information in real-time, between both men and systems.

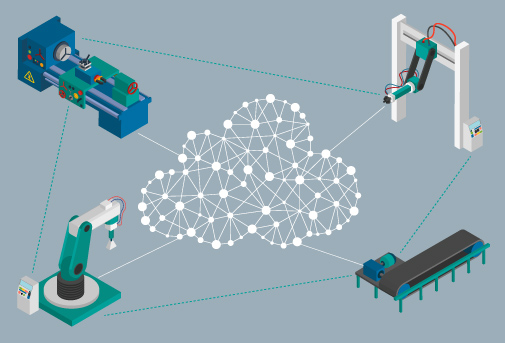

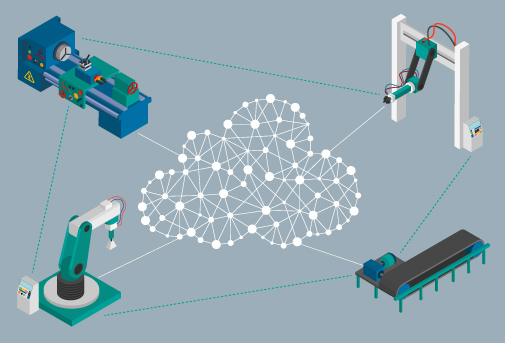

Therefore, today, we can speak of Lean Manufacturing in regards of a decentered model of production, where machines are able to communicate among themselves in real time and independently (Internet of Things paradigm). This means that, thanks to digitalization and Cloud computing, production plants in Industry 4.0 will be able to auto-optimize, auto-diagnose and auto-configure.

It is clear how, in this context, the role of Lean Production is even more valuable. Not only that, also the applications of this philosophy will increase. Yes, because with the ability to exchange important information (i.e. consumption data), it becomes easier to optimize production processes. In other words, you can produce more and faster, with less waste: which is the goal of Lean Manufacturing.

With this purpose in mind, ESA Automation creates solutions for industrial automation based on the principles of Industry 4.0 and IoT, such as our Cloud service or the remote maintenance platform Everyware.

Find out more about ESA Automation software solutions for Industry 4.0.