SPS Italia 2022 was a success, hinting multiple prospects for the future. From 24 to 26 May, 36,522 visitors and 802 exhibitors gathered in Parma to share an itinerary in industrial automation and digitalization. The journey highlighted the most innovative technologies for Industry 4.0, including some of ESA’s latest solutions.

SPS 2022: focus of the event

The fair for intelligent, digital and flexible industry was reconfirmed as a key event in the industrial landscape. From robotics to digital, hundreds of exhibitors introduced their best technological solutions for the future of the manufacturing sector.

Particular attention was paid to sustainability and enabling technologies. Circular Economy as a new frontier of business, digital servitization, new perspectives on the entire life cycle, life cycle optimization and other related issues were in fact the leitmotif of the event.

“The 10th edition of SPS Italia was a great success! The desire to meet after a long time of isolation was great and the number of visitors was proof of this. It is interesting to see many technological innovations presented in a sector that confirms a constant evolution driven by digitalization and environmental sustainability. Our association was able to present several new initiatives and we hope that the positive sector data presented at the fair will also materialize in 2022. ” Commented Marco Vecchio, Secretary of ANIE Automation.

ESA at SPS 2022

As in previous years, the 2022 edition of SPS Italia was an opportunity to present the latest generation of ESA products. ESA news protagonists of the fair:

- The ESA Lumia modular solution, a new concept of HMI, visualization and control available in Cabin Panel and Vesa Arm versions.

- The new family of LUMIA industrial PCs, available in the Book, Mini and Rock variants for maximum versatility.

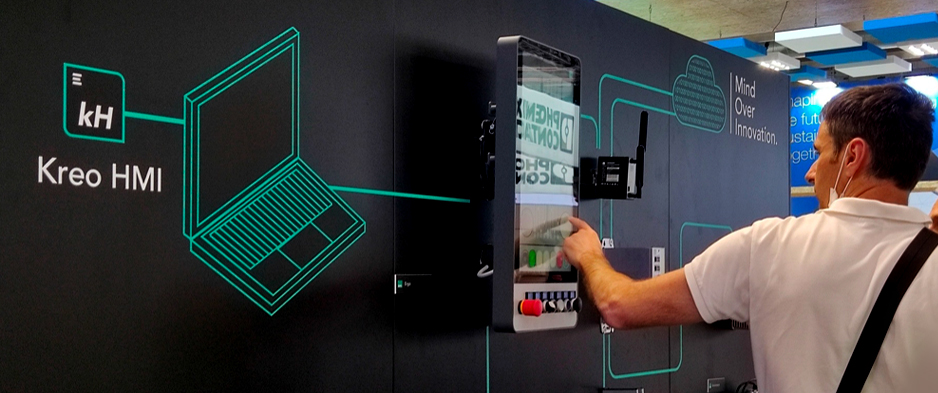

- KREO HMI, the new responsive and platform independent platform for the development of Edge-node and Web-HMI applications according to the Industry 4.0 paradigm.

- MOTUS, the new servo drive that combines maximum flexibility and high performance.

Our industrial automation solutions were not the only protagonists of the ESA exhibition area. Thousands of visitors had the opportunity to discover and observe the ESA Robotics universe in action. For the occasion, a cell with a kuka robot palletizer was installed, equipped with a special shell with sensors to make it collaborative. All controlled by one of our LUMIA115, with project interface created through KREO HMI.