Big Data, Italian Growing Market

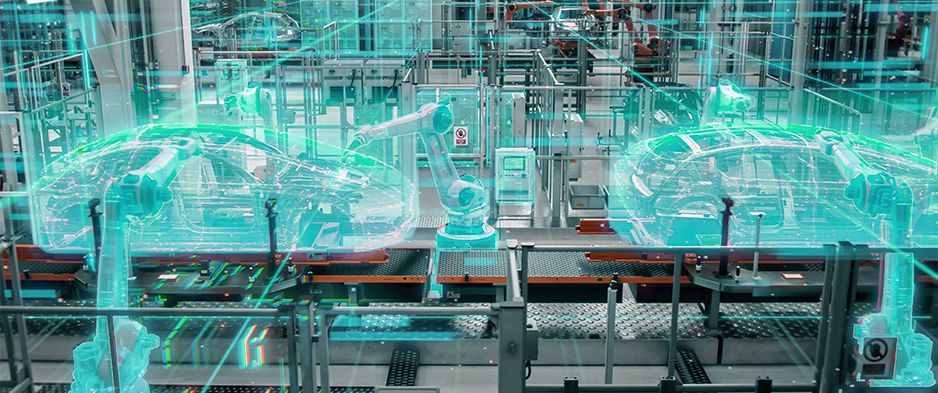

(EN) SPS Nuremberg 2022 ends with positive results. The first live edition after the pandemic records almost 44,000 visitors who met the approximately 1,000 exhibitors present. Like every year, ESA also took part in this tour by presenting some of the latest industrial automation solutions.

Big Data, Italian Growing Market

(EN) In 2022, the Italian Big Data market will grow by 20% compared to 2021 and reach a value of over 2.4 billion euros. This was revealed by the research of the Big Data & Business Analytics Observatory presented during the conference “Data-driven culture: connecting algorithms and people.”

ESA LUMIA HMI+PLC

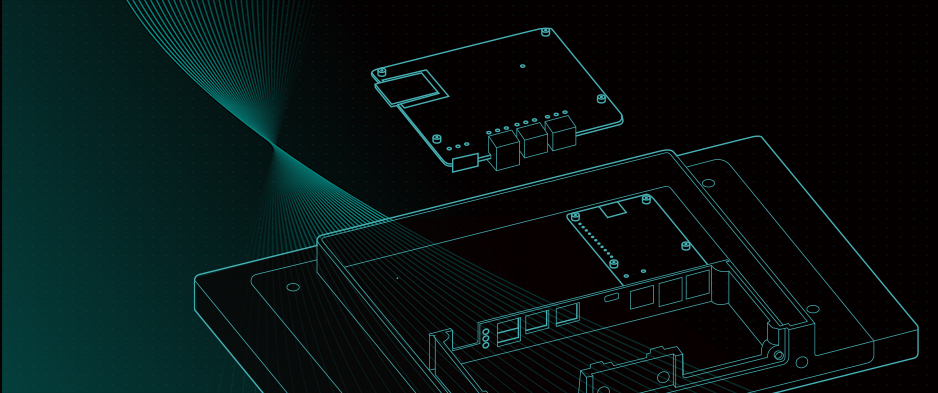

(EN) Visualization and control in a single solution. LUMIA HMI + PLC is a compact device that integrates user interface, machine control cycle, and management of the axis movement. In this way, it supports the operational efficiency of production plants, making it ideal for various applications.

Energy Efficiency in Industry: Enabling Technologies

(EN) Energy saving is one of the hottest topics of the moment. Following the Russia-Ukraine conflict, rising electricity prices forced companies to implement strategies to cut consumption. This has accelerated the transition to efficient energy management solutions, supported by government initiatives such as the United Nations 2030 Agenda for Sustainable Development.

KREO HMI: Distributed Automation Meets the Web

(EN) KREO HMI is ESA’s new tool for creating powerful, intuitive and web technology-based supervision applications. From configurability of the work environment to scalability of the edgeHMI/webHMI architecture, we discover the main advantages of this new solution for industrial automation.

Industry 4.0: 50% Software Bonus

(EN) More incentives with a 50% software bonus. It’s the Italian government's move to enhance support for investments in Industry 4.0. The goal is to promote technological and digital transformation for businesses and, at the same time, to counter the effects of the political and military crisis in Ukraine.